- الأخبار/

- الصفحة الحالية

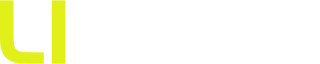

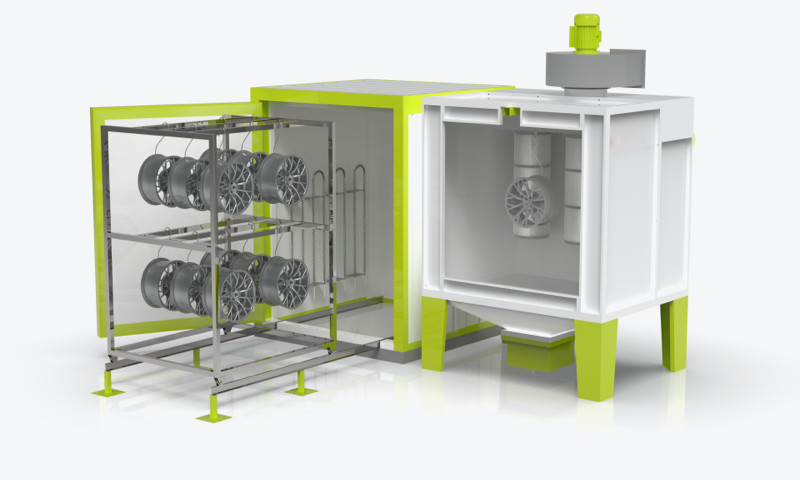

In-depth Analysis Of Four Advantages Of Electrostatic Powder Spraying Equipment Spray Gu

Sep 02,2022

1. Safety: There is no high voltage electrostatic generator in the electrostatic powder spraying equipment. The stimulation of high-voltage electric shock will always make people nervous, and there is no metal electrode in the friction gun, and there will be no spark discharge caused by short-circuit of the electrode during spraying to ignite the gas-powder mixture.

2. Convenience: It is very convenient to spray with the friction gun. First, the friction gun is not connected to the high-voltage cable, so it is convenient to hold; second, it is less affected by the spraying distance. The friction gun is closer and farther away from the workpiece, and the spraying effect is similar.

3. High efficiency: There is no metal electrode in the friction gun, so the phenomenon of electrode powder accumulation will not occur, avoid the falling off of the accumulated powder on the electrode, and ensure the smooth and smooth surface of the powder layer. The friction gun can spray thicker coated wires, spray small workpieces or workpieces with complex surface shapes, which is much better than the high-pressure gun.

4. Saving: The charging of the friction gun powder is caused by the friction between the powder and the gun wall, which determines that the friction gun does not need a high-voltage power supply - an electrostatic generator in electrostatic spraying. Thus saving 10-30% of equipment investment, especially for small test equipment, the saving ratio is higher.